Surface Grinding

After the alternation of resilient fabric, the needles on fillet card clothing are smooth and the angles are consistent.

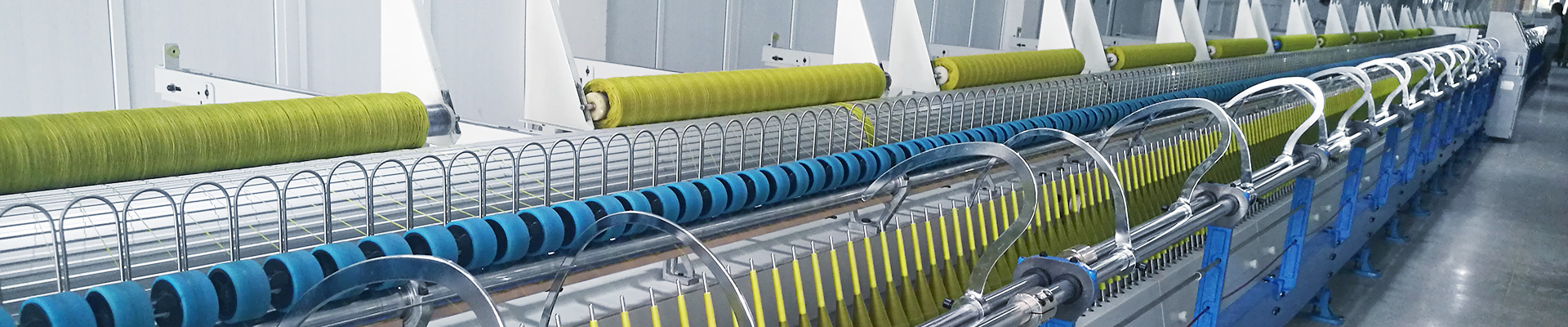

The actual operation is shown in the following figure, dual rail high-speed grindings move in a horizontal reciprocating motion, and the grinding wheels are installed on bilateral grinding wheel heads.

Side Grinding

After surface grinding process onto the elastic needle. The process of side grinding can be conducted onto the side of the needle, the sharpness of the needle top will be restored after this process.

The actual operation as shown in the figure, the grinding head conducts reciprocating motion, 2 groups of side grinding wheels are installed respectively on the grinding wheel shaft at both sides of grinding heads, each group has 4 side grinding wheels. The side grinding wheels are inserted into the space between needles and rub the upper part of the needles with high speed rotation to realize the sharpness requirements.

Polishing Function

After side grinding process onto the upper part of the needle. The process of polishing can be conducted onto the needles in order to eliminate the burrs.

The actual operation as shown in the figure, the grinding head conducts reciprocating motion, 2 groups of polishing brushes are installed respectively on the grinding wheel shaft at the both sides of grinding head, each group has 4 polishing brushes. The polishing brushes are inserted into the space between needles and rub the upper part of the needles with high speed rotation to realize the smooth requirements.

Service :400-616-3535

Service :400-616-3535

Tel: +86 512 63365510

Tel: +86 512 63365510

Fax:+86 512 63341238

Fax:+86 512 63341238

Wechat:szylfg_public

Wechat:szylfg_public

Add:No.9, East KaiFa Rd, Wanping Community, Taihu New Town, Wujiang District, Suzhou, China

Add:No.9, East KaiFa Rd, Wanping Community, Taihu New Town, Wujiang District, Suzhou, China